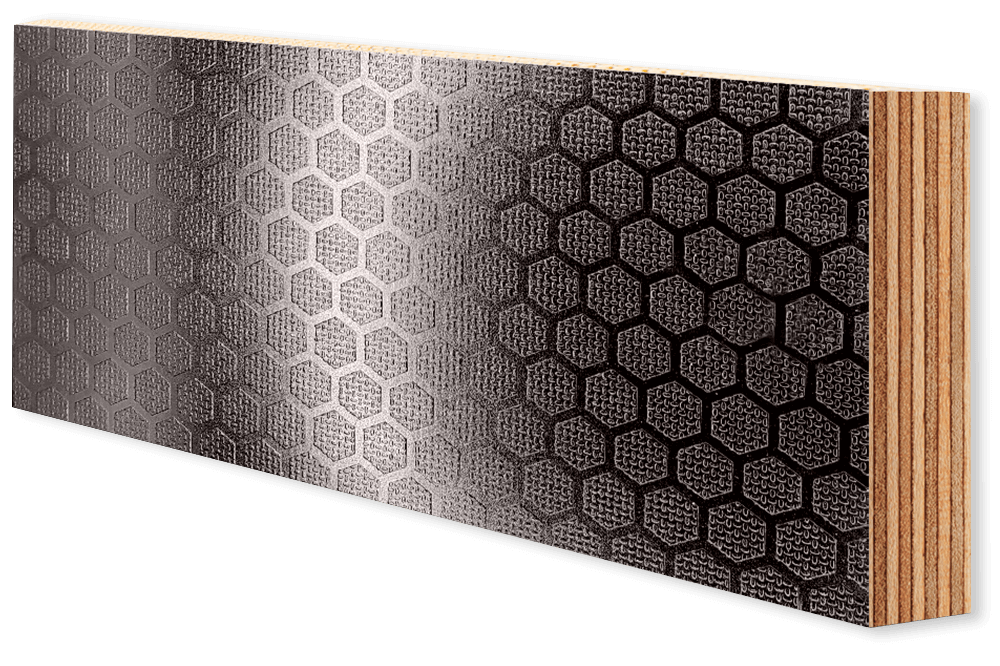

PANDAforest Tongue & Groove OSB

Anti-Skid

Full Birch

Eco-Friendly

Custom

FEATURES & BENEFITS

◎ Faster and easier laying, saving time and cost

◎ High cost performance and low price.

◎ Smooth surface; no core voids, knots or splits.

◎ Good sound insulation, high stiffness and ability to withstand significant snow and wind loads allow to use.

◎ We have the flexibility to customize specific properties, lengths, widths.

◎ Edge seal helps prevent moisture intrusion and water-related issues that can lead to call backs.

◎ Suitable for uses not permanently exposed to the weather (exposure 1 panel).

◎ Available in 8-ft, 9-ft and 10-ft lengths.

◎ Available in tongue and groove profile for easy installation

◎ Environmentally safe construction material.

◎ High strength and stiffness

◎ Strong and uniform consistency throughout.

◎ Support FSC and PEFC legally harvested resources. and is E1 emissions compliant.

◎ Support OEM/ ODM service.

END USE

◎ Wall Sheathing - interior and exterior walls. OSB panels can be used with all types of interior and exterior finishing materials

◎ Roof sheathing- OSB panels as an underlayment for shingles, concrete and metal tiling, slating and other roofing materials.

◎ Subfloor - can be used both as continuous flooring and load bearing joists

◎ Single floor – in light structures OSB panel can be used directly as flooring.

◎ Furniture –frames of upholstered furniture, chairs, cabinet furniture, home built-in furniture (coat closets, shelving units, wall wardrobes)

◎ I-joists – supporting floor and wall structures in timber houses.

◎ SIP panels - Manufacturing consisting of two outer OSB layers and a core polystyrene foam layer.

◎ Stiff basis - for thermal panels

◎ Formwork Plywood - Overlayed OSB panels can be used repeatedly as a concrete formwork.

◎ Plank - Stairs, landings, scaffoldings

◎ Fence - temporary construction site fencing.

◎ Partition wall - partition walls for ships and railcars

◎ Structures for auto vehicles, trailer floorings and truck bodies

◎ Packing - Shipping crates and pallets packing materis.

◎ Deck - shelving units, exhibition stands, furniture shelves, shop counters, table tops, bill boards.

◎ DIY

Specifications

| Type | Size | Layer up | Weight (kg/sheet) | Core Materials | Packing Unit (sheets) | ||||||

| T&G | 1220x2440x12mm | cross-oriented | 22 | Mixed Combi | 65 or 75 | ||||||

| T&G | 1220x2440x15mm | cross-oriented | 27.5 | Mixed Combi | 45 or 60 | ||||||

| T&G | 1220x2440x18mm | cross-oriented | 33 | Mixed Combi | 43 or 50 | ||||||

| T&G | 1220x2440x21mm | cross-oriented | 38.5 | Mixed Combi | 37 or 45 | ||||||

| T&G | 1220x2440x25mm | cross-oriented | 46 | Mixed Combi | 31 or 37 | ||||||

| T&G | 1220x2440x28mm | cross-oriented | 51.5 | Mixed Combi | 27 or 32 |

| FORMALDEHYDE EMISSION:E0 ≤0.03 | |||||||||||

| Layer up:Cross-oriented | |||||||||||

| Moisture Content:8% – 15% (at time of despatch) | |||||||||||

| Dimensional Tolerances:±0.3mm | |||||||||||

| Straightness:±1.5mm | |||||||||||

| Density:580 kg/m³ (approximately) | |||||||||||

| Adhesive:E0 | |||||||||||

| Joint Group:For nails, bolts and screws | |||||||||||

| Finish:Unsanded faces, sanding / T&G / paint edges. | |||||||||||

| Branding:Each pallet of PANDAFOREST OSB is branded as least once with the product name for identification and evidence of compliance with manufacturing control standards | |||||||||||

| Storage:Store on level bearers at maximum 1800mm centres well clear of the ground, and cover to keep dry but allow ventilation | |||||||||||

| Source:Plantation timber |

Apart from the regular standard dimensions of 1220mm x 2440mm, also special thickness lengths are available (thickness form 6mm-28mm, max lengrh 6000). Special dimensions available by request – there may be requirements for minimum quantity per special dimension.

-

Design Eveything

-

Technology Support